Castings & Liners

Tube Mill Internals are the several items equipped in a HIS or tube mill, which include an inlet wall at its entrance, liner (to protect its shell and give the media charge the requested effect), a diaphragm and an outlet wall at its end. A tube or horizontal mill is a cylindrical tube positioned horizontally on two supports and is rotating. It can have different dimensions and operating parameters to suit the particular application they are designed for.

Feed end Liner

The role of Feed end Liners is to protect the mill heads against wear. They must also offer the longest possible lifetime. Their application is based on the principle of protection of the flange and design to avoid any projection of balls on the linings.

Feed end Liner

The role of Feed end Liners is to protect the mill heads against wear. They must also offer the longest possible lifetime. Their application is based on the principle of protection of the flange and design to avoid any projection of balls on the linings.

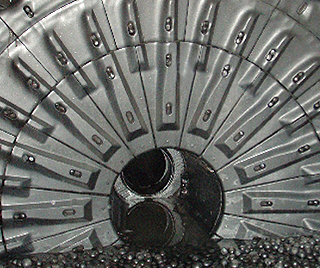

Lifting Liners

Lifting Liners are used to prolong the service life of the mills, reduce the wear rate of the grinding balls and reduce the power consumption and maintenance requirements. Various systems of Lifting Liners are used, depending on the application requirements of the end user, namely, Bolted, Semi-Bolted and Vaulted effects.

Lifting Liners

Lifting Liners are used to prolong the service life of the mills, reduce the wear rate of the grinding balls and reduce the power consumption and maintenance requirements. Various systems of Lifting Liners are used, depending on the application requirements of the end user, namely, Bolted, Semi-Bolted and Vaulted effects.

Diaphragms

Improved grinding media and liners can do much for productivity but the benefits can be reduced without equally efficient diaphragms. Mill diaphragms are exposed to high loads and stresses. The intermediate diaphragm divides the tube mill into two grinding chambers with different grinding ball sizes and maintains a material level in the first chamber for optimal pre-grinding. The discharge diaphragm is individually adapted to the existing mill and is fixed either on the mill head or mill shell. The open lifter diaphragm is installed between the drying and the first grinding chamber of a raw mill. The double outlet diaphragm is used in mills with a central discharge.

Diaphragms

Improved grinding media and liners can do much for productivity but the benefits can be reduced without equally efficient diaphragms. Mill diaphragms are exposed to high loads and stresses. The intermediate diaphragm divides the tube mill into two grinding chambers with different grinding ball sizes and maintains a material level in the first chamber for optimal pre-grinding. The discharge diaphragm is individually adapted to the existing mill and is fixed either on the mill head or mill shell. The open lifter diaphragm is installed between the drying and the first grinding chamber of a raw mill. The double outlet diaphragm is used in mills with a central discharge.